PC Diffusion Film A35 Series

PC Diffusion Film A35 Series

PC diffuser PCDF:

PCDF (Micro Structure Diffusion Board) is a new type of optical diffusion material produced by using imported optical grade raw materials and scientifically matched optical grade organic diffusers imported from the United States and Japan through the extrusion process of the 10,000 grade dust-free workshop. At the same time, the surface has a microstructure treatment. The principle is to integrate the light diffuser and scientific optical design, so that the light incident on the sheet can be fully reflected and refracted at different angles. It has the optical characteristics of high diffusivity, high haze, and high transmittance, which can be effective The point or line light source is transformed into a soft and uniform surface light source. On the premise of achieving good light transmittance, it also has good light source lattice shielding. It is an ideal optical material for you to solve the secondary light distribution of LED lamps and lanterns. , It is the best light diffusion material for LED flat light masks.

The second-generation six-sided matrix micro-structure expansion film, under the premise of the best performance of high fog and high transparency, has innovatively added a brightening function to realize high fog and highlight. The upper layer of the backlight module can replace the traditional three-layer film (upward increase, downward increase and upward expansion), which saves the cost for the majority of users.

Appearance: The milky whiteboard is translucent, with few crystal points, high light transmission, high smoothness and good flatness.

Super impact resistance: 250 times the strength of ordinary glass, more than 150 times that of tempered glass, and 30 times higher than that of tempered glass. Therefore, it will not break in the event of various accidents. Better protect your property and life safety.

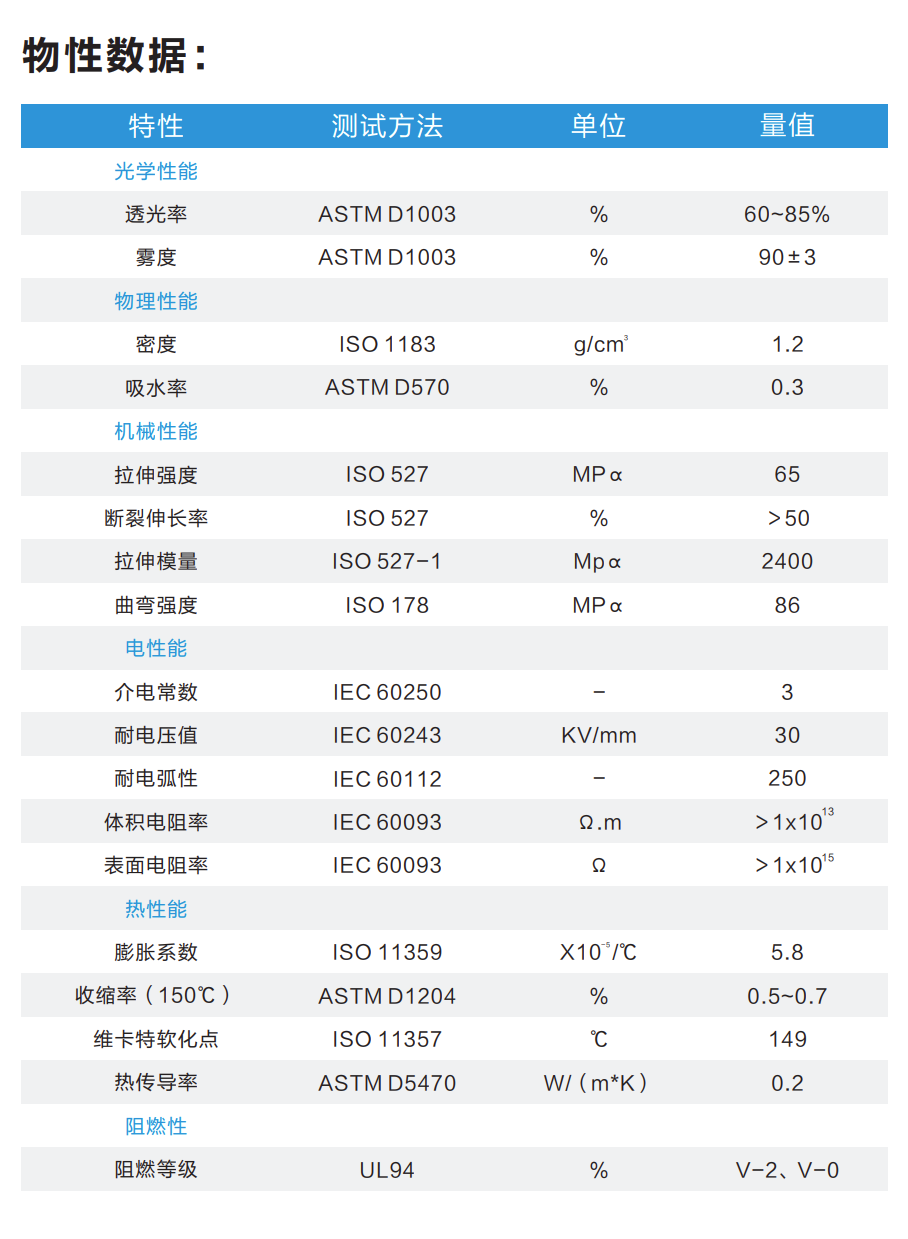

Construction performance: The density of PC is 1.2, and the weight is only 1/2 of that of glass, so the weight is lighter, which is convenient for construction and reduces costs.

UV protection: This product is made of 100% imported UV-resistant new materials, which can not only prevent UV damage to indoor products, but also effectively extend the service life of PC panels.

The flame retardant grade is UL-94: V-0~V-2, with excellent fire resistance, and no toxic gas will be produced during combustion.

Weather resistance: This product can adapt to harsh weather conditions from -40°C to 120°C and still maintain its performance. And combustion will not occur.

PCDF (Micro Structure Diffusion Board) is a new type of optical diffusion material produced by using imported optical grade raw materials and scientifically matched optical grade organic diffusers imported from the United States and Japan through the extrusion process of the 10,000 grade dust-free workshop. At the same time, the surface has a microstructure treatment. The principle is to integrate the light diffuser and scientific optical design, so that the light incident on the sheet can be fully reflected and refracted at different angles. It has the optical characteristics of high diffusivity, high haze, and high transmittance, which can be effective The point or line light source is transformed into a soft and uniform surface light source. On the premise of achieving good light transmittance, it also has good light source lattice shielding. It is an ideal optical material for you to solve the secondary light distribution of LED lamps and lanterns. , It is the best light diffusion material for LED flat light masks.

The second-generation six-sided matrix micro-structure expansion film, under the premise of the best performance of high fog and high transparency, has innovatively added a brightening function to realize high fog and highlight. The upper layer of the backlight module can replace the traditional three-layer film (upward increase, downward increase and upward expansion), which saves the cost for the majority of users.

Appearance: The milky whiteboard is translucent, with few crystal points, high light transmission, high smoothness and good flatness.

Super impact resistance: 250 times the strength of ordinary glass, more than 150 times that of tempered glass, and 30 times higher than that of tempered glass. Therefore, it will not break in the event of various accidents. Better protect your property and life safety.

Construction performance: The density of PC is 1.2, and the weight is only 1/2 of that of glass, so the weight is lighter, which is convenient for construction and reduces costs.

UV protection: This product is made of 100% imported UV-resistant new materials, which can not only prevent UV damage to indoor products, but also effectively extend the service life of PC panels.

The flame retardant grade is UL-94: V-0~V-2, with excellent fire resistance, and no toxic gas will be produced during combustion.

Weather resistance: This product can adapt to harsh weather conditions from -40°C to 120°C and still maintain its performance. And combustion will not occur.